Because there are so many varieties of heat transfer materials on the market today with lots of different projects that they can be used for, people often ask: What kind of specialty paper do I need? How can I choose the right heat transfer material?

In this post, we are going to discuss what heat transfer material is, the types of heat transfer material available today, their differences, and how to choose the right heat transfer material for your project.

Let’s begin!

What are Heat Transfer Materials?

The term “heat transfer material” is a catchall phrase used to describe virtually all materials that rely on heat to affix any design or graphic decoration to an item.

These materials come with a heat-activated adhesive to apply any form of graphic decorations onto different substrates that can withstand the heat of transfer such as T-shirts, bags, caps, etc.

Many years back, the term “heat transfer material” refers to a heavy plastic film with a shiny surface and rubbery feel, affixed to garments.

This “old school transfer material” usually cannot survive through too many laundry sessions before it cracks and peels off.

It was popular in souvenir T-shirt shops where customers picked out a design from a collection of stock transfers and then chose a blank T-shirt.

But in recent times, the world of heat transfers has witnessed a lot of improvements, giving rise to new types of heat transfer materials, processes, and formats.

Types of Heat Transfer Materials

1 – Heat Transfer Paper

This type of heat transfer material is used to transfer printed designs to garments (such as fabrics with cotton and cotton blend or synthetic fabrics like nylon, polyester, and Lycra) when the heat is applied.

This specialty paper works by printing a design on it using a laser or inkjet printer, then heat pressing it onto a garment to transfer the design.

Heat transfer papers can nicely and permanently transfer designs onto garments because their adhesive can bind the ink and fabric together.

With this heat transfer material, you can transfer full-color graphics or designs of multiple layers to your garment – this makes it the easiest and most efficient method for printing detailed graphics or designs onto garments.

Heat transfer papers are available in two different categories – light and dark heat transfer papers.

Light Heat Transfer Paper

Light heat transfer papers are perfect for printing or transferring designs onto white or light-colored garments or fabrics.

Typically, this type of transfer paper requires mirroring an image before printing and has transparent polymer coatings that help to maintain a level of vibrancy on its final result.

Since printers do not require white ink for print jobs, the paper uses the light or white color of your garment as a substitute. That means the empty spaces in your design will show up on the garment as it is.

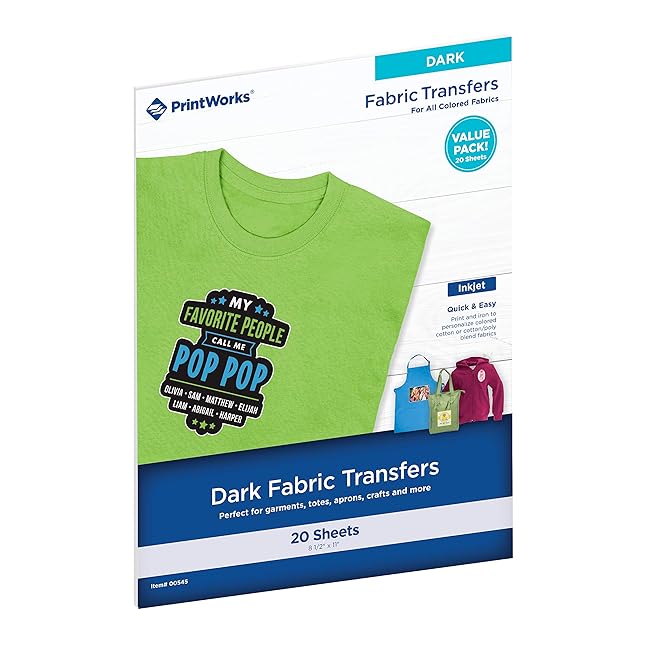

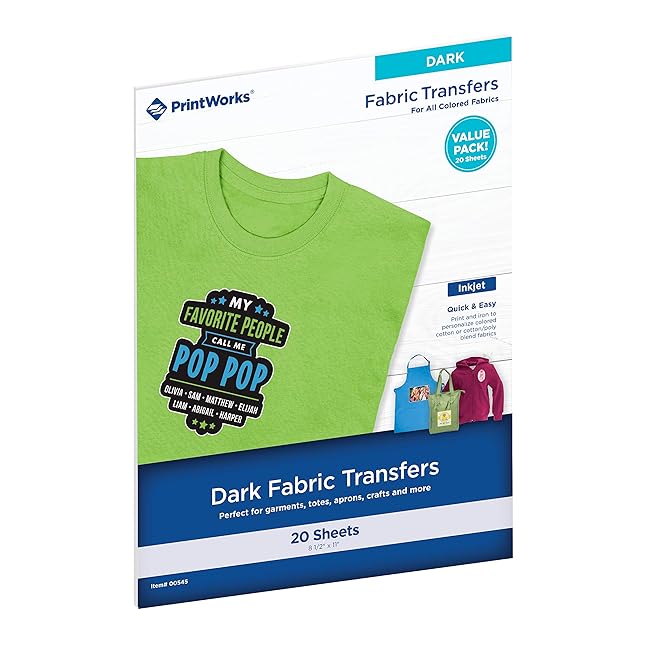

Dark Heat Transfer Paper

Dark heat transfer papers are designed for printing or transferring designs onto black or dark-colored garments.

Unlike the light heat transfer papers, you don’t have to mirror your design before you print it.

They are darker, opaquer, and thicker than the light transfer papers due to their rubber layer base that contains white colored material.

While light heat transfer papers use the color of the fabric for the empty spaces on your design, dark transfer papers use the white material of the paper itself.

That means the color of your garment will not show through the unprinted areas or empty spaces in your design. Your graphic design will transfer just as you designed it.

However, you should always remember to trim your design with scissors or cut with a cutter to remove any spot that does not contain your printed design.

That is because any bit of paper with no print on it (which you fail to remove) will show up as ‘white’ on your dark-colored fabric.

Pros and Cons of Heat Transfer Paper

- It requires less space and is environmentally friendly.

- Prints are durable.

- Very easy to use, even for beginners

- Requires less amount of time to create graphics and make prints

- Good for printing designs involving multiple colors.

- Can make photo-quality prints

- The slightest error during application can damage the entire design or fabric.

Learn more about different types of heat transfer papers in the below section.

2 – Heat Transfer Vinyl

Heat transfer vinyl (also known as iron-on vinyl) is a material with a heat-activated adhesive backing that allows it to bond permanently to a fabric or other surfaces that can withstand the heat of transfer.

To use this type of heat transfer material, you need to create your design on your computer and transfer it to a vinyl cutter to cut out the material according to your design.

After that, you can heat press the cut-out material (iron-on vinyl) onto your garment to decorate it.

Heat transfer vinyl is cost-effective for fewer garment production and is perfect for simple designs and designs with full color or spot color.

There are many different types of iron-on vinyl, each with its unique characteristics, so you have to select the type that suits your design and garment perfectly.

However, heat transfer vinyl is not the best option for intricate designs or designs with multiple colors, especially when you have a large order to deal with.

That is because it requires a lot of time to create, cut out, weed, and apply the complex design or the design for each color you want to print.

Pros and Cons of Heat Transfer Vinyl

- Relatively cheap

- Perfect for jersey and t-shirt lettering

- Lots of options to choose from

- Easy to apply and can work with all kinds of fabrics

- Weeding can be difficult, especially for complex and detailed designs

- Not ideal for multicolored designs or complex designs with small details

- Large-scale production is expensive and time-consuming

- Transfer feels heavy on the garment

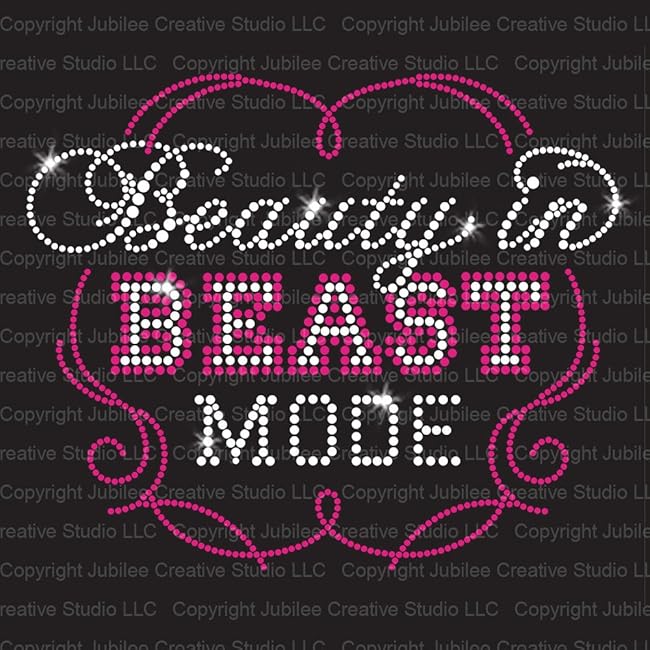

3 – Rhinestone Transfers

Rhinestone transfers are faux gems used to decorate or add sparkle to garments and their accessories.

This shiny, eye-catching imitation diamond is available in different colors and sizes and comes with flat backs and heat-activated adhesive. So, you can arrange them according to your preferred design and heat press them to your garment.

Rhinestone transfers are a beautiful selection for many garment decoration projects.

However, it cannot work with leather, non-porous surfaces and water-resistant materials, but works well with other fabrics.

Pros and Cons of Rhinestone Transfers

- Beautifies and adds sparkle to garments

- Available in different colors and sizes

- Requires skills and a specific set of tools

- Can be a bit difficult to create and apply

4 – Embroidered Patches

Embroidered patches (otherwise known as cloth badges) are pieces of embroidery that can be sewn or heat pressed on garments.

Embroidered patches can be in the form of fashion emojis, cute slogans, and unique animal figures.

They are created with an embroidery machine and embroidery software using threads and fabric backing to achieve a powerful and expressive texture.

They are mostly used for logos and used to show individual names, rank, membership in an organization, sports team preferences, and more.

The back of the embroidered patch design is coated with a sealant that serves as glue when heat pressed and helps to maintain the definition and quality of the design.

The use of heat-applied embroidery is a neat and efficient way to affix the patches to the garment since it requires no sewing line.

However, the patches may not be durable enough to withstand a lot of rigorous washing and usage unless they are sewn into the garment.

Pros and Cons of Embroidered Patches

- Works with almost all fabrics

- Creates detailed graphics design with depth or texture

- Designs are very durable, so it will not wear away

- Design reproduction (especially for logos) is not 100% accurate

- Not suitable for extremely lightweight fabrics

- Requires a lot of time to create the design

Types of Heat Transfer Paper

Inkjet Transfer Paper

This transfer paper is intended for use with inkjet printers.

It comes with a special coating that can help to transfer designs to fabrics using inkjet ink and printer and is suitable for both dark and light-colored garments.

Sublimation Heat Transfer Paper

This material relies on a scientific principle known as sublimation to transfer designs to garments.

Designs are printed on paper with sublimation ink, which turns to gas, solidifies, and attaches to the fabric permanently when heat and pressure are applied.

The sublimation process prevents ink smudging during application and produces high-quality photo prints.

Sublimation transfer papers are not suitable for cotton; they are perfect for synthetic garments like polyester and polyester blends.

This printing method is costlier than inkjet printing since inkjet printers are more affordable than sublimation printers.

So, you should consider using this method only when you have large orders or a large customer base.

Plastisol Transfer Paper

Plastisol transfer paper (otherwise known as hot-split or hot-peel) helps to print designs with the same quality as a screen-printed image.

To use this paper, you have to print your design on it with a screen printer, heat press it onto your garment, and then peel off the paper.

Although plastisol works with a wide array of fabrics, it limits you in terms of color variety. Also, it is not as expensive as sublimation but requires expensive specialty equipment.

Cold-Peel Screen-Printed Heat Transfer Paper

Also known as parchment paper, a cold-peel transfer paper shares some similarities with plastisol in terms of screen printing and costly specialty requirements.

With this paper, you have to wait for it to cool down after heat pressing before you peel off its paper backing.

While you wait for the paper to cool down, it transfers ink to your fabric to provide you with a brighter and clearer image.

How to Choose the Right Heat Transfer Materials

By now, you should know the difference between the types of heat transfer materials available, as well as their benefits, drawbacks, and when to use each.

However, some of these transfer materials come in different types and with different properties so selecting the right one for your project can still be a challenge especially if you’re a beginner.

To make the right choice, there are some factors you need to consider. These include:

The Contents of Your Fabric

If your garment is made of cotton, polyester, or cotton-poly blend, then you should go for a material that is compatible with it.

You should also check if your garment is stretchy or heat sensitive and select the material that can go with it.

Note: transfer papers and some iron-on vinyl are compatible with stretchy or heat-sensitive garments; rhinestones are not suitable for stretchy or heat-sensitive garments.

The Complexity and Colors Included In Your Design

While vinyl works best with simple designs, transfer papers work best both simple and complex designs.

However, if you wish to use other types of heat transfer materials, you should consider the ability to add all the colors you want to add, and the time required to create and apply your design.

Go for heat transfer papers if you want to make multi-colored or photo-quality prints, heat transfer vinyl for simple designs with a single color or a full color with gradients and shading.

Select embroidery for logos or textured multi-colored designs or rhinestone or Holographic HTV to add sparkles to your garment.

The Number of Garments You Want to Produce

If you are producing in a large quantity, you should consider the time constraint and cost-effectiveness of using each transfer material before you proceed.

For instance, heat transfer vinyl is cheap but requires a lot of time to cut out and weed your design, so it is not recommended for large orders.

Embroidery also takes longer to create, so you may have to check your production deadline before you choose this material.

Conclusion

We hope this guide provides you with a little more understanding of how to navigate through heat transfer material options and helps you decide which material to go with for your project!

If you have any questions or need help selecting a material for your project, do not hesitate to contact us.