“What laser engraver should I buy?” is usually the first question that pops up after someone decides to explore the idea of setting up a laser engraver business.

The market is quite diverse, full of different models suitable for various applications. Finding the ideal laser engraver machine can take some time and requires a bit of patience if this is the first model you’re purchasing.

Don’t worry though – as long as you understand your situation and your basic requirements, finding a suitable laser engraver is easier than it seems at first.

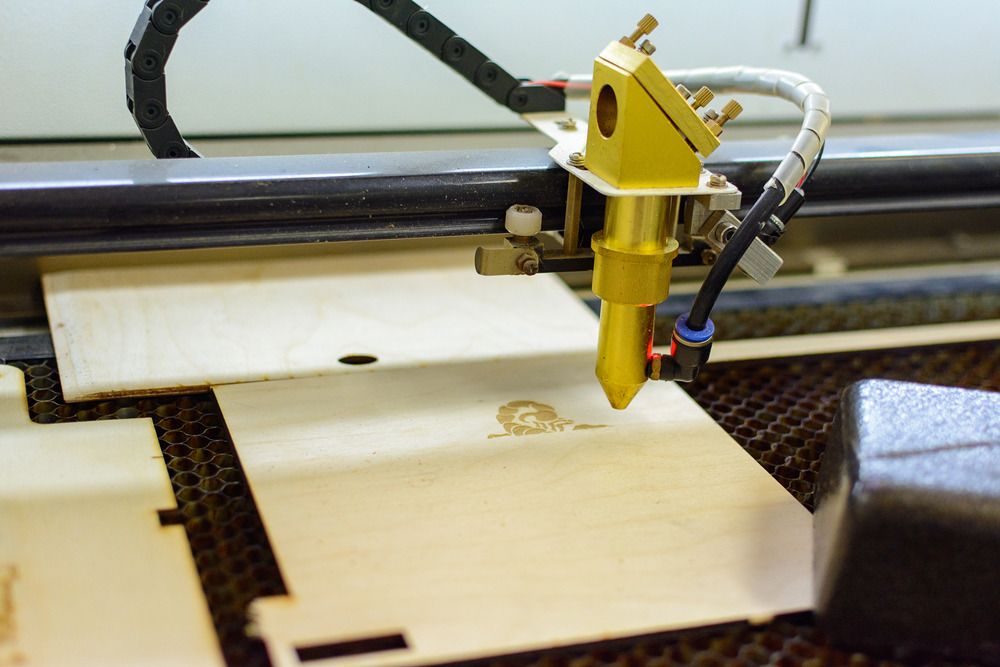

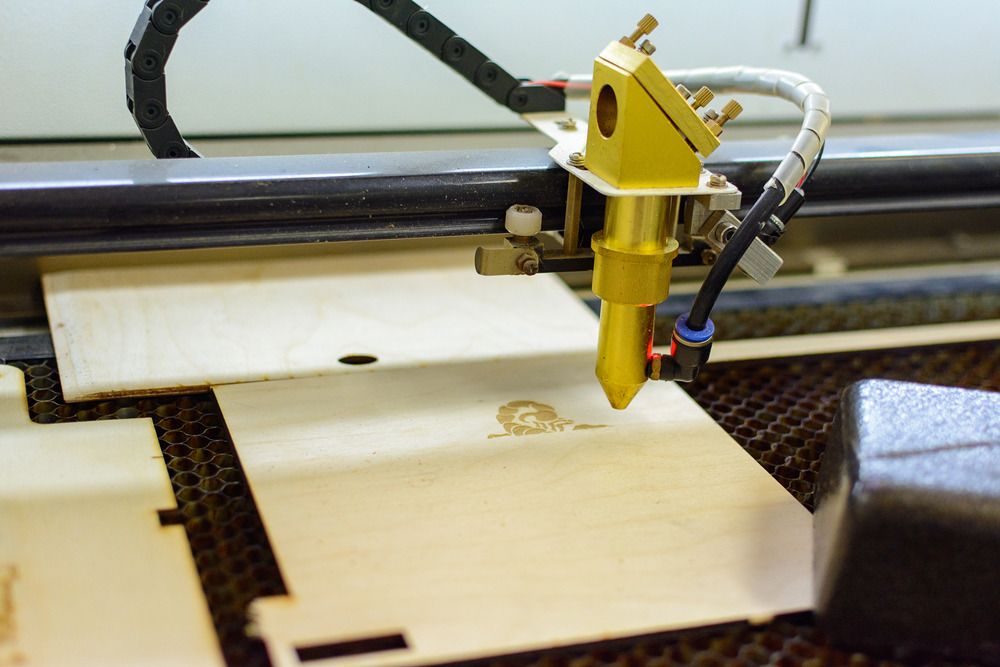

How Does a Laser Engraver Work?

A laser engraver works by heating the surface of the working material to very high temperatures, enough to cause vaporization. This leads to the development of crevices which trap light.

Those crevices might seem shallow – they usually don’t go deeper than around 0.5 mm – but they are more than sufficient to create patterns that can be seen by the naked eye.

A home laser engraver might work at a smaller power rating for safety reasons. But it will still provide enough heat to achieve the desired effect. Sometimes, it might take longer to complete the engraving process, especially with certain materials that are more resistant to heat.

Knowing how to use a laser engraver and familiarizing yourself with its inner workings is important before you start your first project. There are various safety precautions that are important to observe, and you also risk compromising the final quality of the project if you aren’t sufficiently familiar with how the engraver works.

Pretty much all modern laser engravers are compatible with popular design software. This means that you can easily create your design in a program like Photoshop or AutoCAD, and then have it transferred to the laser engraver.

You may need to use an intermediate medium for the transfer if your laser engraver can’t be connected to your computer directly. But in any case, the final outcome is the same – the machine takes the input data and transfers it to your medium of choice.

Because of the evaporation caused by exposure to the laser, it’s important to work in a well-ventilated room. Some laser engraver models also feature an integrated exhaust system that can help keep harmful fumes away from your body and from the room as a whole. If you work in a tight enclosed space, it’s recommended to go with a model of this type to minimize any health hazards.

How to Choose the Right Laser Engraver

Choosing the best home laser engraver means finding a good combination of several factors, including the budget you’ve set for the purchase. Knowing what to look for in a laser engraver from the start will save you a lot of time in your search.

1 – Supported Materials

Laser engravers can work on a variety of materials. While wood and metal are the most commonly used ones for laser engraver projects, they are far from the only option you have. You can also use acrylic, plastic, or even paper.

If you have a specific project (or project line) in mind, it’s important to ensure that your chosen laser engraver will support the material you want to work with. If you want a model that supports a wide range of materials, you may have to spend more.

2 – Precision

A well-constructed laser engraver with a high-precision drive will result in more accurate, aesthetically pleasing engravings. It will also allow you to perform engravings with much finer detail, which can make all the difference in complex art with a lot of twists.

If you are only going to engrave basic things that don’t have a lot of intricate detail to them, spending more money on an advanced laser engraver with a high level of precision may be a waste. Make sure that you actually need all that extra accuracy before purchasing a particular model, because that alone can add a double-digit percentage to the final price.

3 – Convenience

If you plan on running a business with your laser engraver, you should also make sure that it’s as convenient to use as possible. This includes various factors: how easy it is to hook up the engraver to the power supply, whether it supports directly connecting to a computer for the transfer of images, and how much maintenance it requires (see above).

It’s often a good idea to spend a bit more on the convenience factor if it means reducing the time you spend on each engraving. This might not mean much on the scale of each individual engraving, but it can quickly add up over time if you produce multiple engravings every day.

4 – Brand

Look into the brand itself. Some are well-known on the market and don’t require any special introduction. However, there are also plenty of smaller companies that produce laser engravers which have not established a significant market presence yet.

You should not ignore those, as you might miss out on some good deals that way. The popularity of the laser engraver market has attracted the attention of a lot of new companies. Just because a company was established very recently doesn’t mean you should automatically discard it as an option. Make sure to do some research into who runs the company and what their current track record is.

5 – Size

Size will matter a lot if you’re running this business out of your own home. Remember, you won’t be storing just the engraver itself, but you’ll also have to make room for all materials and supplies you use in your daily work.

If you ship your products yourself, you must also have enough space for all the packaging materials you’ll use, which can add up very fast.

6 – Maintenance

Generally, laser engravers need relatively little maintenance over time. You might have to regularly replace the lenses, but that’s about it. Unexpected maintenance is a different story though. A laser engraver utilizes lots of moving parts, especially if it’s a more precise model with a more accurate drive. Those can occasionally break.

Replacing those parts is not always straightforward and you may need to have your laser engraver repaired by a qualified technician in those cases. If you buy a model that breaks down all the time, you will quickly accumulate lots of maintenance costs which can eventually even overshadow the price of a more expensive engraver.

7 – Portability

If you want to switch between several different locations for your work, you should look into a model that’s easy to transport and set up. Some laser engravers are meant to be installed once and then rarely moved afterwards.

However, keep in mind that going for extra portability usually means compromising other factors, especially versatility and performance. Portable models can also cost more.

8 – Price

Obviously, you’re going to want to balance all performance, convenience, and maintenance factors with a good price. This is the tricky part, and the one that usually requires the most research. You should have a clearly defined budget from the beginning, as that will allow you to exclude some options right off the bat.

But at the same time, try to keep your budget flexible to some extent if that’s possible. Sometimes the ideal model for your needs will be more expensive by just $50 – $100. If you’re buying something to use for business purposes, it’s usually smart to go a little further and invest into a model that will truly cover all your requirements and last a long time.

9 – Support

Ideally, you won’t ever have to reach out to the manufacturer for support. But it’s good to know that you can rely on them in this regard. That’s why working with a company with an established reputation is sometimes preferable.

Again, don’t ignore small companies just because of their lack of market presence by default. But also look into the level of support you can expect to get in case you run into any problems.

FAQ

Are a laser engraver and laser cutter the same thing?

Laser engravers and laser cutters are fundamentally the same machines. The difference lies in how they are used. A cutter is set up in a way that separates entire chunks of the working material, while an engraver just creates permanent marks into it.

How strong of a laser engraver do I need?

This depends on the materials you want to work with. For something like paper or leather, a simple low-powered laser engraver should do the trick. However, if you want to work with metal or stronger plastics, you will have to invest in a high-powered engraver instead.

What size laser engraver should I get?

The size of your laser engraver will be determined by what you want to engrave. Small things like wallets and keychain trinkets can be done with some of the smallest laser engravers on the market. On the other hand, if you want to engrave large pieces like laptop covers or even artworks, you should purchase a laser engraver with an appropriate size.

What type of laser engraver should I buy?

The engraver’s laser strength will be the main deciding factor in your purchase, once you’ve aligned all other factors as described above. You should also prioritize models capable of operating fast if you want to use your engraver for business purposes.

Which laser engraver brands are the most reliable?

Orion and Ortur are both well-known brands with established market presence. Atomstack is another relatively popular company on the market.

Conclusion

Now that you know how to choose a laser engraver suitable for your projects, all that’s left is to make the purchase and start stocking up on engraving materials and supplies.

And of course, don’t forget to set up your store as early as possible. This is not something you want to leave for the last minute, as it involves a lot of work that can be hard to anticipate.