With the demand for printed products at an all-time high, sublimation prints stand out and set new heights as far as customization of blank products goes. Sublimation decorations are preferred by many decorators for their no-feel texture and long-lasting images.

Moreover, you get bright and colorful images that will make a statement in any setting and add a unique charm to the apparel or merchandise.

But now that you have expressed admiration for the well-made sublimation prints and have an interest in the concept, you need to have innate know-how and understanding of how sublimation printing works before you can hit the ground running.

The good news, the sublimation process is no rocket science. Ahead, you’ll find all the information you need to equip yourself with if you desire professional-quality sublimation customizations.

What is Sublimation Printing?

Haven’t heard of sublimation printing yet? By the number of people who swear by it, the bags of queries we get, and discussions on the web today, you’d be in the minority.

Sublimation printing is a heat transfer technique for decorating blank apparel or items with at least 50% polyester composition or substrates with a polyester coating. Here, a gel sublimation ink is used to print the image or design on a sublimation transfer paper.

When the transfer paper is placed on the blank item you will be printing and heated in a heat press, the heat transforms the solid sublimation ink directly into a foggy gas without first melting into liquid. The heat also opens up the pores on the substrate to allow gas particles to penetrate the substrate, bond with the polymer in the polyester, and become part of it.

When the gas cools, it solidifies the matrix of the material forming the design. Therefore, there won’t be any inks drying to the printed object. The graphics produced are permanent and fully embedded into the fabric or item.

Pros & Cons of Sublimation Printing

Pros

- Durability – Sublimation printed designs are very long-lasting. Remember, the transfer occurs at a molecular level making them permanent and free from fading, distortion, and cracking. This makes sublimation designs ideal for everyday items that you will use and clean constantly like sportswear, mousepads, kitchenware, and more.

- Vibrant colors – You will not go wrong with sublimation if you desire true to life images with nature’s own depth of color and vibrant details that almost pop at you.

- Non-textured – with the design infused into the fibers of the fabric or material, there will be an additional layer to the fabric and no feel of the graphic to the hand.

- Simple and straightforward – The process is also simple and straightforward even if you are just getting started and does not require any special skills or tools.

Cons

- You are limited to items made of polyester or at least 50% polyester.

- You can only sublimate on white or light-colored substrates since there is no white sublimation ink. The materials must be of white or light color as well. Sublimation inks used the white in the substrate as the base layer for the artwork. Sublimation printers work by mixing base colors and using recipes from the design software. Unfortunately, none of the base colors can be mixed to come up with the color white. This explains why sublimation printing does not support color white.

What Can I Do with Sublimation Printing?

Sublimation is a practical technique for;

- Customizing graphic apparel

- Home and personal items decorations

- Printing works of art and pictures

- Product decorations

- Promotional printing and advertising display

- Signage

- Customized exhibits and logos

Sublimation Printing vs DTG

Besides sublimation printing, direct-to-garment (DTG) transfer is another firm favorite for many. DTG is a method of product decoration that uses surface adhesion to embed designs onto fabrics, primarily cotton.

The beauty of DTG printing is the simplicity of the system. All you need are transfer papers and a DTG printer. The DTG printers use inkjet print heads that move horizontally to apply or print the graphic directly on to the apparel. The image is then cured or dried using a heat press or garment dryer.

So how does it compare to sublimation printing?

- In direct-to-garment printing, the image is printed on top of the material unlike in sublimation printing where the ink penetrates and the image is embedded within the fibers of the fabric.

- Another aspect that sets the two printing techniques apart is the fact that you will not need to transfer papers when doing DTG designs whereas sublimation printing demands that you invest in sublimation papers.

- Sublimation printers also boast up to eight base color models meaning higher color accuracy and vibrancy. Meanwhile, most DTG printers only offer up to 4 base colors for mixing.

- DTG printing has one plus, you can print on colored surfaces. A chemically engineered ink called white ink is available. So, you can print in white and create base coats on dark colored fabrics in color white. On the contrary, sublimation printers do not produce and usually leave white areas in the design open or blank.

- Moreover, while DTG primarily relies on design software like Adobe Photoshop to create digital artwork, sublimation printers come with custom printer drivers, color palettes, and profiles that enhance the quality of the design.

- As far as the cost goes, starting up with DTG printing can cost you a kidney. One limitation of direct-to-garment printing is the outrageous price of DTG printers. Most of them run upwards of ten thousand dollars and can cost a ton to maintain. On the other hand, a rock-solid sublimation printer ranges anywhere from $400 to $2500.

Can You Print Sublimation on Any Printer?

The answer is no. This couldn’t be further from the truth. Unlike your ordinary printer which simply deposits ink on to the top of the transfer paper, the dye-sublimation printer for t-shirts is designed to work with sublimation ink cartridges and sublimation transfer paper.

There are three types of printers which can support sublimation printing:

- Sublimation printers specifically built for sublimation.

- Inkjet printers with sublimation compatibility. You can also convert an already existing inkjet printer which can work with a CISS ink system to support sublimation, especially Epson and Sawgrass printers. You will need to replace the printer head, use sublimation paper, and replace the regular ink cartridges with sublimation ink cartridges.

- Specific workforce printers with the sublimation function (Rear).

You need to check the specifications of the printer and ensure that it is sublimation friendly and can support sublimation printing.

What is Sublimation Ink?

Sublimation ink is a heat-sensitive gel solution that can turn from solid to a gas without going through the liquid phase when heat and pressure are applied. The ink is a product of a dye-based and water-soluble formula that is made from natural ingredients like plants. The dry base formula is dissolved in de-ionized water and mixed with alcohol as drying agents.

The main benefit of sublimation ink is that they last longer than most dye-based inks and produce designs that will not crack, peel, wash away or fade. Another bonus is the fact that the inks have a small molecular size so you get vivid and crisp images with super fine details and brilliant lifelike colors.

What Are Sublimation Blanks?

Sublimation blanks are items sold with white or light-colored, non-printed surfaces that have been intentionally pre-treated and coated with polyester to make them sublimation ready. The material should not be heat sensitive and should be able to stand up to the heat without melting, getting ripped or wrinkled.

The most common type of sublimation blanks is blank apparel like t-shirts, sportswear, and caps made of polyester, lycra, polyamide, and other sublimation-friendly fabrics. Some kitchenware and utensils such as cups, mugs, plates, and more come with a special coating making them sublimation friendly.

Not just that. You can also purchase preprinted photo frames and photo tiles and print your desired artwork. Additionally, smaller blanks such as ornaments, key chains, mousepads, and other gift items are also available on the market.

Other companies also offer advertisement banners, flags, umbrellas, gaming table covers, and felts that are pre-coated for sublimation. You can also go for sublimation-friendly hard substrates such as skis, and snowboards.

Which Materials to Use for Sublimation Printing?

This point cannot be overstated. Sublimation transfers can only be applied to polyester materials and polyester resin-coated products. Some of the materials that are treated for sublimation include;

- Polyester, nylon, and spandex fabrics used in clothes, hats, footwear, mousepads, backdrops, tents, flags, banners, and table covers.

- Plastics items and fiberboards such as cell phone cases and utensils

- Wood and hardboard used in skateboards, snowboards, photo frames, etc.

- Ceramics e.g. tiles, home décor, ashtrays, and ornaments

- Glass items like dinnerware and display windows

- Aluminum used in kitchenware, keyrings, and other lightweight products

- Leather e.g. footballs

What Heat Press to Use for Sublimation?

There is a wide variety of heat press machines on the market today ranging from small inexpensive presses for small scale products to massive and pricier options for commercial use. And while most well-made heat presses will deliver desirably with sublimation printing, you should avoid using press irons. We recommend heat presses for their consistent and even heat and pressure that you won’t find in ordinary iron presses.

If you intend to sublimate on small items like t-shirts and caps, small format heat presses should serve you just fine. But if you plan on going pro and print on flags, banners, and other larger surfaces, large format presses or calendar presses will be your go-to option.

Flat heat presses will work as well in large format pressing as they do in small items and unique surfaces such as hardboards, aluminum, and ceramics. Designers who want to embed colorful artwork around curved surfaces and irregular shapes should look out for 3D vacuum presses.

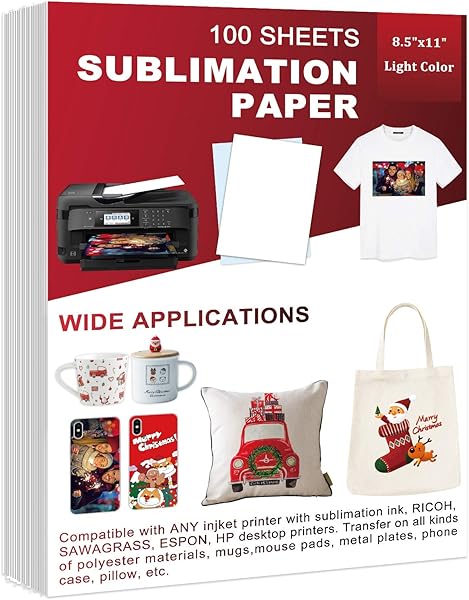

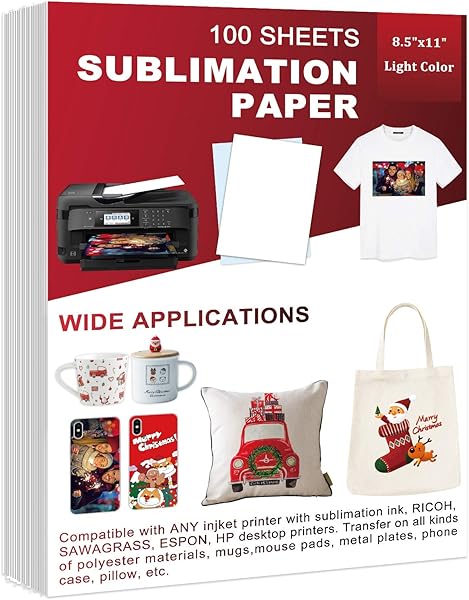

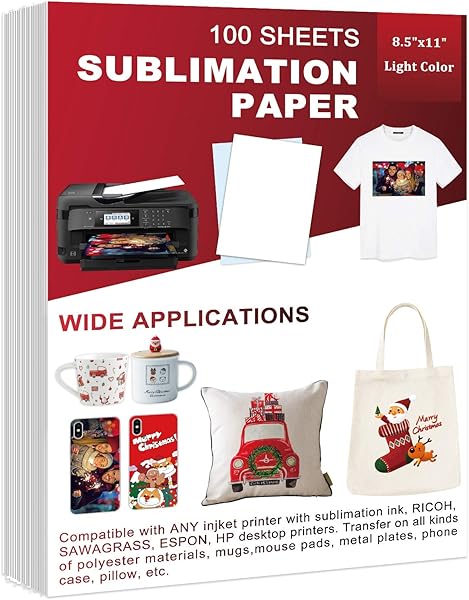

What Kind of Paper is Used for Sublimation?

Sublimation paper is not your typical transfer paper. It is specially designed from top quality, heat-resistant substrate paper. The paper is then treated with a special silica and binder coating that holds and locks in the dye and keeps the ink intact.

When heat is introduced, the papers will readily release the ink into the print fabric. After you’re finished pressing the garment, you will still need to strip the tape off. Sublimation paper is the priciest among all other transfer papers courtesy of the top-notch quality of the paper.

It is crucial to always check the instructions on the transfer paper for the recommended temperature you should use. Ensure you adjust the temperature, and timing to the specified setting on the transfer paper you are using.

What Other Supplies Will You Need to Do Sublimation Printing?

Protective gloves

Make sure you put on protective transfer gloves to keep your hands safe from burning when handling very hot items from the heat press.

Thermal tape or Spray Adhesive

It is of the essence that you get a heat resistant tape for securing the transfer paper to the blank, holding it firmly in place, and prevent movements when pressing. Shifting of the paper may lead to ghosting which lowers the quality of the transfer.

Sublimation wraps and cover sheets

If you notice the sublimation ink bleeding on to your heat-press, consider enlisting the aid of silicone or Teflon coversheets.

Foam pillows

Pillows are handy when you are printing on heat-sensitive fabrics and would wish to protect from the harsh direct heat of the press. And if you hate press lines as much as I do, then using foam pillows is one sure way of keeping them at bay.

The Basic Sublimation Printing Process

Dye sublimation can be a one-step or two-step process depending on whether you have a printed ready-to-transfer paper, or you need to make one.

What you Need

- Sublimation printer with sublimation ink

- Computer with design software installed

- Heat press

- Sublimation paper

- A sublimation blank

- Pair of scissors

- Protective gloves

Procedure

#1 – If you do not already have a printed sublimation paper, identify the artwork or graphic you want to print.

#2 – Use your design software to manipulate the color profiles of your artwork, and design it the way you want. The program will also let you mirror the image in case of a text or number on the image. Thankfully, some sublimation printers come with their free proprietary software from the manufacturer.

#3 – Insert the blank transfer paper in the sublimation printer and print the image on to the sublimation transfer paper. Ensure you are printing on the film side of the paper

#4 – Trim off or weed any blank parts around the sublimation transfer paper that are not colored with the artwork using a pair of scissors. Trimming prevents blank areas from being transferred to the substrate.

#5 – Open the press and quickly wipe clean the print surfaces to remove any lint or ink from previous and dirt, dust, and particles that may affect the quality of the print.

#6 – Switch on your heat-press machine. Depending on the instructions on the transfer paper set the temperature to the recommended setting and give it time to heat up.

#7 – Test print the design on a standard paper or an old garment you do not mind throwing. Check that the colors are well represented and the details or texts are well-positioned and aligned. Fix any spelling or logo errors as soon as you notice them.

#8 – Gently place the sublimation blank on the platen of the press with the side you want to be printed facing upwards. If you are printing on apparel, it is advisable to pre-press it and remove any wrinkles. Ensure the surface is even.

#9 – Place the transfer paper facing down on the surface you intend to print on.

#10 – Pull down the handle to close the press then punch the start button and wait for the timer to go off. Afterward, press the power off button, pull up the handle to open the press, and remove your garment.

#11 – Allow the transfer to cool for a moment before peeling off the transfer paper from your garment to remain with the finished design

Precaution!

- Wash sublimation printed products in cold water

- Dry them in cold temperatures

- Avoid harsh detergents like bleach. We recommend powdered detergents

- Keep washing brushes away from the oriented graphics.

Final Words

There’s never been a more exciting time to be a product decorator. All thanks to the introduction of sublimation printing, you can enjoy permanent, vibrant, and photo quality graphics that will withstand a lifetime of abuse.

So, do not hesitate to take the bold step today and toss your feet into the exciting and creative journey of sublimation printing. It will be the best thing you will, at any point, do in your career as a designer or decorator!