Whether you are a beginner, a hobbyist, or a professional, you will agree with us that some accessories and machines are indispensable, especially when it comes to the production of our favorite pieces.

In today’s world of crafting, one of the tools we cannot do without that help with imaging, craft work, and other work of art is a vinyl cutter.

However, this powerful and versatile tool can be a bit overwhelming, especially if you’re new to vinyl cutting and crafting since you probably don’t know all of its capabilities yet.

In this vinyl cutter basics guide, we will provide you with the basic knowledge of vinyl cutter and vinyl cutting to get you started on your vinyl cutting and crafting journey.

We will also show you the type of vinyl cutters that are available on the market today as well as the features you should look for to meet your cutting requirements.

Now let’s dive right in.

What Is a Vinyl Cutter?

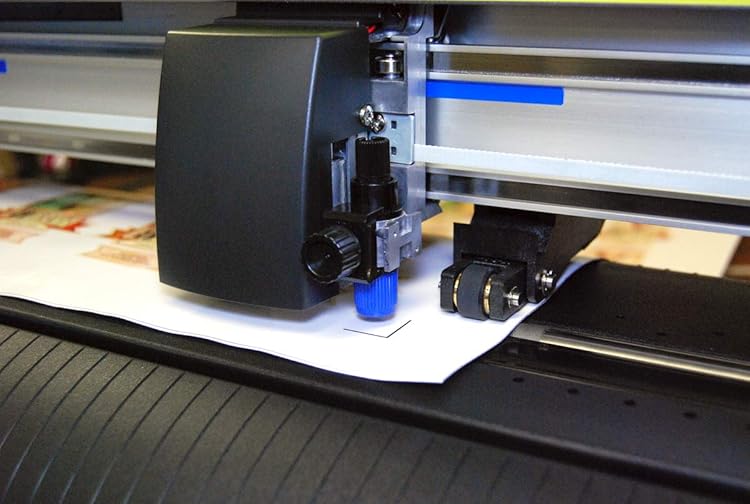

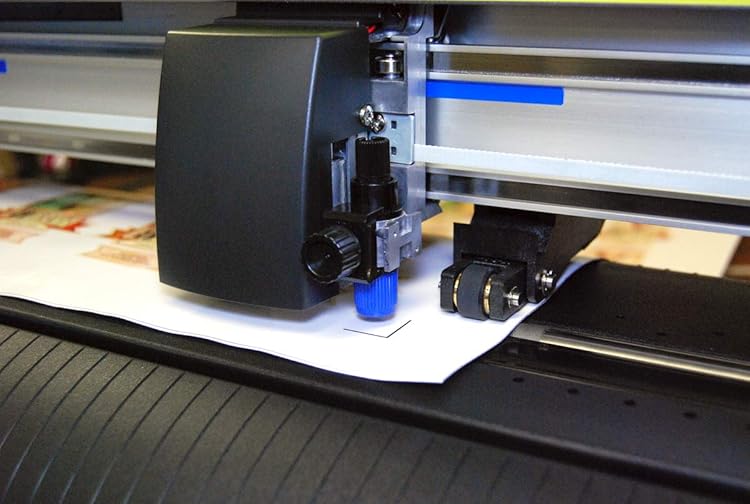

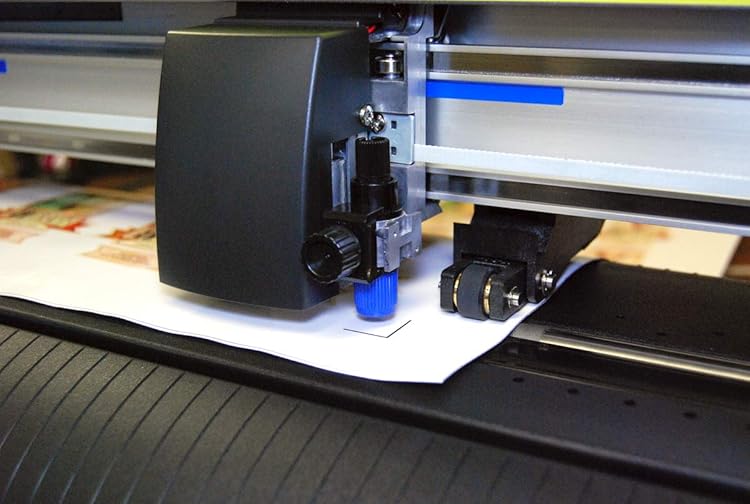

A vinyl cutter (also known as die-cutters, craft cutters or vinyl cutting machine) is a computer-controlled device that is used for cutting vinyl and other materials into shapes.

This machine looks and often behaves like a desktop printer, but it uses a blade to cut specific designs into a supported material instead of printing the design on the material.

Some vinyl cutters can be connected to a computer via cord or Wi-Fi to import a specific design to the machine and cut it out. Others make use of cartridges to figure out your design before the cutting process.

Once the cutter gathers the information about the design you want to cut, it will control the movement of its blade according to your design and make incisions in the material to cut out your design.

The invention of the vinyl cutting machine dates back to the year 1888 when an inventor from Canada created a machine that could cut through fabrics.

Although this machine was difficult to operate and occupied a large amount of space, it initiated the long line of craft cutters that gave birth to the efficient and compact craft cutters that we see today in homes and workshops.

Vinyl cutters allow for creative freedom and are not restricted to cutting vinyl materials alone.

These versatile tools can also cut your designs into a variety of materials such as tissue paper, cardstock, paper, thermal transfer materials, vellum, reflective, and many more. Some models can even engrave your designs on aluminum and wood.

What about Vinyl Cutting?

Vinyl cutting is described as the act of using a software program to create a design and transferring that design to a vinyl cutting machine to cut it out.

The moment the machine finishes cutting out the design, you have to remove the waste vinyl material and use the final design for your desired application.

Vinyl Cutter vs Vinyl Cutter Printer

Vinyl cutter printers (also known as a plotter, or vinyl plotter) work just as a vinyl cutter but are used differently.

Vinyl plotter makes use of a pencil, pen, marker and other writing tools rather than a knife or blade to draw your design on vinyl or other materials.

On the other hand, vinyl cutters make use of a knife to cut your desired pattern instead of just plotting the design on vinyl.

All vinyl cutters can function as a plotter since their blade attachment can be replaced with a pen attachment. However, not all plotters can cut. Plotters also differ from printers in that they sketch your design on the material using a pen with a single color (one color at a time).

Printers make use of ink cartridges to create the representation of the image using a series of dots on paper and can even print multiple colors at a time (especially with colored printers).

What is a Vinyl Cutter Used For?

You’re probably wondering, what can I do with a vinyl cutter – what exactly is the essence of craft cutting?

Vinyl cutters offer limitless opportunities in today’s world of crafting. Although traditionally operated and owned by people in the sign-making industry, they are now an integral aspect in handling different crafts project and creating different types of art.

That is why they are now more popular among professional crafters (those who use the machine for commercial purposes) and hobbyists (people who enjoy crafts and arts at home).

Some of the things you can make with a vinyl cutter at home include:

- Labels and stickers

- Vinyl decals for wallpaper, smartphones, and laptops

- Letters

- Decals

- Banners

- T-shirts and apparel decoration

- Cards

- 3D objects

- Origami

Application of Vinyl Cutting Machine For Commercial Purposes

Most craft businesses invest in the best vinyl cutter for different purposes, which include:

Advertisements: Vinyl cutting machines are often used to cut letters, labels used on commercial products and other signs or designs that are used as advertisements on banners, vans, and automobiles.

Signage Businesses: Vinyl cutters are the staple of sign printing businesses. They are used to create signs for walls, windows, doors, and other surfaces.

Clothing and Accessories: Most clothing businesses make use of vinyl cutting machines for t-shirts, apparel decoration, and the creation of a pattern for making accessories like hats and bags. It allows businesses or individuals to create their own patterns and logos that can be sewed, or heat pressed onto a piece of fabric.

Magnets: Businesses can also use vinyl cutting machines to cut a thin sheet of magnets and make or customize refrigerator magnets.

Home décor: Home décor businesses also benefit from the use of vinyl cutters. The machines are used to cut out designs or create decals for walls, doors, windows, and other surfaces to beautify them.

Types of Vinyl Cutters

There are many different types of vinyl cutters available on the market today. But for better understanding, we will classify them according to their scale of usage and design.

Classification According to Their Scale of Usage

Home use/hobbyist

The vinyl cutters for home use are intended for light use. They are designed for start-ups, hobbyists, and those who enjoy crafts and arts at home.

Vinyl cutters for home use are usually cheaper and cannot work on larger printing surfaces, or provide the precise cutting required by many businesses.

This type of cutter is perfect for small designs and is usually small in size, so they do not occupy too much space.

Also, the type and amount of materials they support are limited. So, if you’re going for this type of cutter, you’ll need to check if it supports your preferred materials and Operating System before you make your final decision and select your personal vinyl cutter.

Mid-pro/Small shop/Workshop

This type of vinyl cutter can work on larger surfaces and supports more materials than those designed for home use, little wonder why mid-professionals use them in small shops and workshops.

Mid-pro vinyl cutters can provide the precise cutting required by many businesses and can cut through tougher and thicker materials.

However, they are usually costlier and come with more innovative features than those designed for hobbyists and home use.

Professional/Commercial Vinyl Cutters

This cutter can handle all vinyl projects as well as many other craft cutting tasks you can think of (especially the cutting tasks required by craft cutting businesses).

They can make precision cuts for complex and intricate designs and can work on larger printing surfaces. Professional cutters come with specialized options and features that are not available on other cutters.

They have higher cutting force, deliver fine detail on small graphics and text, and have higher cutting speed.

They also have superior tracking and can cut through tougher and thicker media and usually support different software and operating systems. However, they are costly even more than the mid-pro vinyl cutters.

Classification According to Their Design

Roll feed design

This type of vinyl cutter has a design that resembles the letter “T” especially when you look at them from the sides and comes with a floor stand that provides them with a solid and sturdy base.

This vinyl cutting machine gives you the benefit of craft cutting from a roll of materials, which saves money than using sheets of materials.

They require loading or feeding the media through its push rollers, which also help to push the media along the pen or blade to print or cut out the design.

Roll feed vinyl cutters continuously roll and cut media and usually come with media guides or media catch baskets to hold the media roll and catch the cut media. Their design allows for easy operation and saves valuable production space.

Roll feed vinyl cutters come in different sizes and support a long roll of media (up to 50 ft long) for long-length cut or print applications.

Flatbed Design:

Flatbed vinyl cutter as its name implies, makes use of a table or a flatbed platform to complete different cutting or plotting tasks.

The media is placed and secured on its working table while the machine moves the pen or blade over the material to carry out different cutting, drawing, and embossing tasks instead of rolling and cutting the media like the roll feed and desktop designs.

Flatbed vinyl cutters are ideal for cutting hard materials that cannot be fed through friction-feed/roll-feed cutting plotter.

They can cut through thicker materials; some models can even cut materials up to ¾ inches; this makes them ideal for cutting intricate designs on other materials like oil board, cardboard, foam material, photo-masking films, and sandblast-resist rubber. Flatbed vinyl cutters come in different sizes.

However, they are a bit more expensive and can occupy more space than the roll feed cutters.

Desktop Vinyl Cutter:

Just like the roll feed vinyl cutters, desktop vinyl cutters come with rollers with which the materials are friction-feed into the machine for plotting and cutting tasks.

Cutters with this type of design require no stand as they can be placed and operated on a desk. They can cut through different sheets of materials, while some models can cut through a long roll of media.

Desktop vinyl cutters are available in different sizes. They are cheaper and are usually not as bulky as the roll feed and the flatbed models.

The Basic Specifications of Vinyl Cutters Beginners Should Know

Selecting a vinyl cutting machine that is perfect for your crafting needs may be overwhelming, especially if you do not understand the specifications of vinyl cutters and the basic terms used in craft cutting.

However, this section will provide some informative guides and definitions of basic specifications and features of vinyl cutting machines, so you’ll know what to look for to meet your cutting requirements.

Size/Cutting Area

This is one of the most important aspects to consider when selecting a vinyl cutter.

Firstly, the amount of space you have in your home or workshop will determine the size of the machine you can buy.

Secondly, the size of your machine’s cutting area will determine the size and amount of materials that can be feed into it.

While hobbyists can go for cutters with small sizes and smaller cutting areas, professionals should go for a professional vinyl cutter with a wider cutting area to handle larger jobs.

Speed

The speed of a vinyl cutting machine determines how fast it can plot or cut and complete your craft cutting tasks. The speed of a craft cutter is usually measured in inches per second or millimeters per second.

High-speed cutters are recommended for professional users who cut a large number of crafts or make use of the tool for commercial purposes as they can help to complete their project in a timely way.

People who require the tool for home use or light usage can go for those with an average speed.

However, the cutting speed of a craft cutter does not determine how precise the cut will be. So, when you’re shopping around, do not consider speed as the most important feature.

Downforce or Pressure

The pressure or the downforce is how hard the cutter presses its blade into the material. It determines the types of materials a vinyl cutter can work with as well as how precise its cut is.

For instance, the blade pressure or downforce of vinyl cutters for home use is not as crucial as it is for commercial vinyl cutting machines and professional vinyl cutters that are used all day for various projects.

The amount of pressure required to cut different materials successfully varies, even if they have the same thickness.

For instance, standard vinyl requires less pressure or downforce than denser material like metallic.

Drive Motor

This is another important feature to consider when selecting a vinyl cutter as it has a huge impact on their functions and performances.

The drive motor of a vinyl cutter is its engine as it controls the grit roller that retracts and advances media and directs the blade and pen across the platen.

There are two types of drive motors used in the vinyl cutting machine – the digital servo motor and the mechanical stepper drive motor, each with its benefits and drawbacks.

The servo motors offer superior tracking and are faster and quieter than stepper motors. While the silent operation of vinyl cutters may not be a big deal in a workshop setting, it can be a very important factor to consider when shopping for a vinyl cutter for home use.

Also, stepper motors are more accurate when working on thinner materials while servo motors are best with thick materials.

On the other hand, Servo motors are more accurate than mechanical stepper motors and cut small letters and designs (up to 1/8 inch) as precisely as it does the larger ones.

However, the servo motors are more expensive and incur a higher cost of repair should anything go wrong with them.

Tracking

This is known as the ability of a cutter to align materials inside it and maintain a straight path accurately. Cutters with enhanced or superior tracking abilities, reduce scraps and require less adjusting, which helps to save time and money.

Cutter with digital servo motors achieves better tracking than the mechanically driven stepping cutters; this makes cutters with servo motors a better choice for long cutting lengths as well as extremely large and small graphics.

Contour Cutting

This is a cutting method that involves cutting through the outline negative or positive offset (contour line) of a printed object to cut out the pre-printed media. This cutting method is suitable for materials like iron on transfer where you can cut away the excess material to have what you only require for your design.

Contour cutting vinyl cutters make use of their blade and a laser pointing device (optic eye) or special Registration Mark to create stickers or decals. This is the most accurate cut available as it can give you a precise cut up to 0.1mm.

Software/Operating System (OS) and OS Compatibility

Just as hardware requires software to operate and function properly, vinyl cutters require design software to send information to the machine on what to work on and complete different craft-cutting tasks.

Software is the computer programs that help you create designs and communicate to the machine what to cut. Most vinyl cutters have their own software that allows you to create your design and transfer it to the machine to cut it out.

Some cutters are compatible with other utility design software and support various operating systems or platforms while others do not. Some cutters are even easier to operate than others even though most of them come with their own design software.

So, when selecting a vinyl cutter, it is important to check the software compatibility of the device and how easy it is to use the design software that is supported by the cutter.

The higher the support for different platforms and design software, the better.

Conclusion

Now that you know the function, types, basic specifications, and features of vinyl cutters, it’s time to select a model that suits your needs and get started on your crafting journey.

If you need more help in finding the right model for your workshop or one that meets your cutting requirements, read our best vinyl cutters review and learn how to select the right one for your needs.