Many non-paper items and documents are exposed to a continual risk of damage, considering their vulnerability to dust, water, and other related elements.

Could you imagine bunking a critical interview, and the valid explanation you have is damaged papers?

While people put immense weight on protecting key documents for presentation and ensuring they’re in pristine condition for decades, lamination ensures all-around presentability of all materials.

How does Laminator Work?

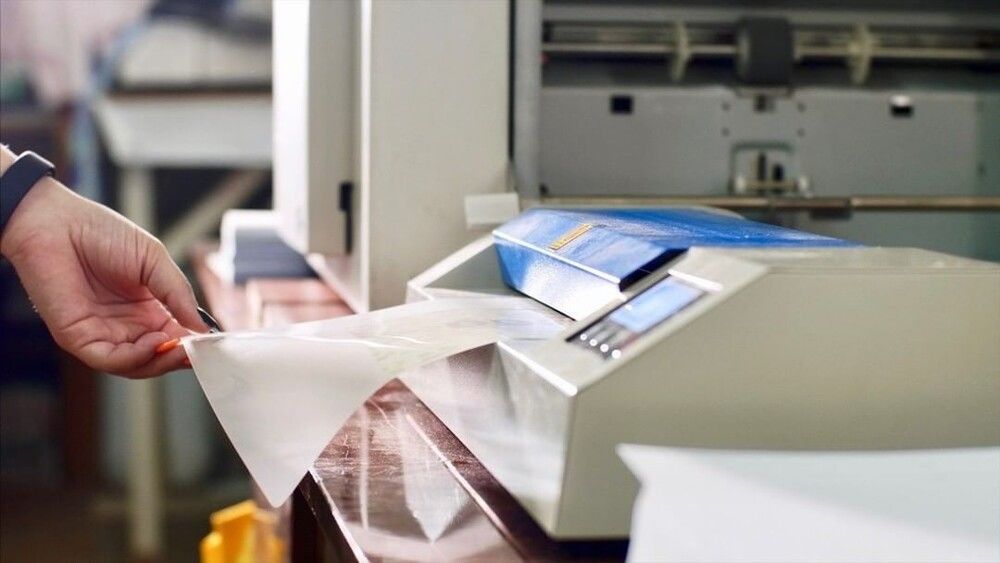

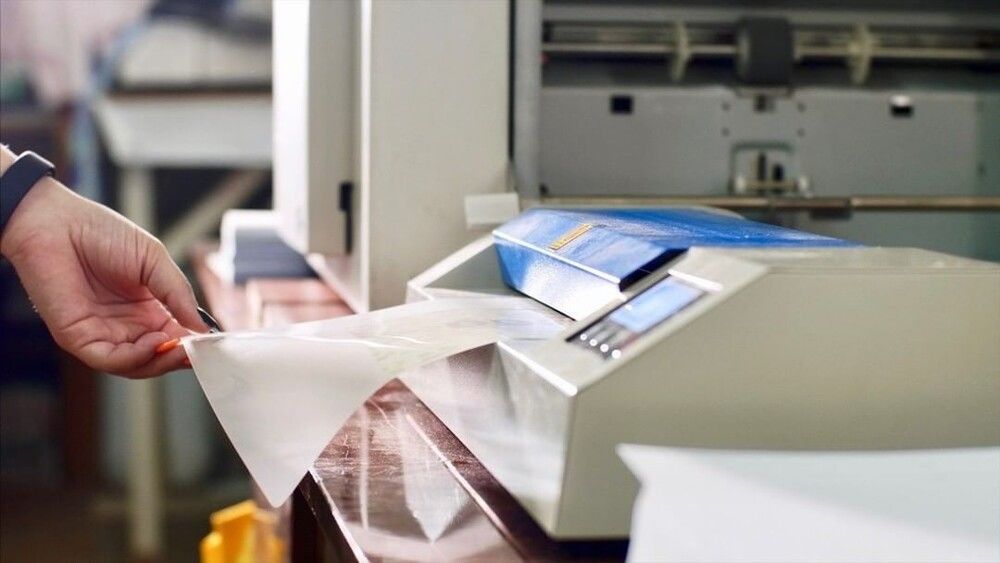

A laminating machine works by sealing the valuable item by covering it with a protective plastic film on either side of the document.

The core purpose of a laminator is to provide sturdiness, aesthetics, and durability of the paper.

Typically, the laminator uses a combination of pressure, heat, and an internal roller mechanism to sandwich papers in plastic lamination pouches.

Most modern pouches work by placing the document around the pouch – with an adhesive placed extensively around its edges – then feeding the paper into the machine.

The laminator then applies pressure or heat (depending on the category) to form a tight bond around the document and seal all the corners.

While high-end laminators allow the user to adjust the temperature settings, the roller tends to lose some heat during pressing. You’ll have to wait a short time before feeding the next document.

Types of Laminating Machines

Laminators are categorized by the way they employ the lamination process. In general terms, the laminators feature in one of the primary configurations below:

1 – Cold Laminators

This laminating machine is a non-heat version used to handle documents that might be sensitive to extremely high temperatures.

Unlike the typical hot lamination process, cold laminators exclusively apply pressure to seal an adhesive plastic film wrapped around the document.

As a new laminator on the scene, the cold laminator presents a mammoth of perks since it’s handy in areas without power or in outdoor activities.

Examples of documents laminated using this process include some photographs, documents with vinyl or adhesives, or carbon copies. While cold laminators are generally cheaper, pouches used with this cold laminator are relatively expensive.

- The exclusive use of pressure and adhesive ensures water tightness

- Suitable for areas with no power source

- The machines are safer since they don’t employ any heat

- The rigidity of the laminated document is a bit compromised due to the exclusive application of pressure and adhesive.

2 – Pouch Laminators

A pouch laminator is generally more comfortable to use, smaller and uses pre-defined sizes of plastic pouches with an adhesive lining.

It works by placing the document inside the pouch, after which the pouch is placed inside the machine. Like film lamination, the two films of plastic adhere to the document when heated, consequently encasing the paper in the pouch.

One of the most excellent perks of the pouch laminator is its incredible flexibility. From home to office and commercial usage, you will likely encounter this laminator in everyday scenarios owing to its extensive usage environment.

Pouches have various sizes – ranging from 3 to 10 mils. Documents encased in 10 mil pouches are generally thicker while those encases in thinner pouches bend relatively easily.

- The machines are generally smaller and can be carried around easily.

- It’s relatively affordable compared to roll laminators

- You can only laminate documents of specific sizes, limiting you to the papers that can fit your pouch.

3 – Roll Laminators

The roll laminators, also known as film laminators, are the most common machines found in schools and larger organizations.

They are generally just about any size and used to laminate documents on a large scale by trimming them once finished. The film laminator uses two layers of film for sealing by incorporating the top layer inside the machine.

Lamination begins by placing a document at the bottom layer of the film and feeding it into the machine. Some hot rollers apply pressure and heat on the top layer – against the material – as the item passes through the laminator.

This category of laminators is generally flexible and is used where large scale production of laminated items is imperative.

- You can process a wide range of document sizes

- The machine can laminate documents in a continuous series

- It is suitable for large-scale processing

- Slightly costlier than smaller pouches

- It is generally larger and occupies more space

Different Uses of a Laminating Machine

There are several laminating machines for handling various documents, with the majority found in many offices and homes today.

The most common types of documents sealed by a laminating machine include:

- Posters

- Book covers

- ID badges

- Scrapbook pages

- Stickers

- Programs and menus

- Photographs

- Business cards and

- Certificates

From embellishing and protecting documents to speed and effectiveness, laminating machines are highly convenient, making them used for professional results extensively and in many large corporations.

Generally speaking, the primary reason for laminating documents is to preserve their quality by preventing them from folding and giving them a long life. Before selecting a laminating machine, it is imperative to understand the mammoth of the advantages of obtaining one.

- It enhances the quality of paper and photos.

- The sealed barrier prevents fingerprint damage, stains, and moisture.

- It improves document durability by making the paper stiff and thick.

- Laminators offer a straightforward and flexible way to protect documents, business cards, Photographs, IDs, and resumes.

- It has incredible flexibility in school, home, business, and personal usage.

Tips for Choosing a Laminator

The primary consideration you’ll make before choosing a laminator is your document size, the purpose for usage, and how often you’ll be using it.

Some of the most common varieties found in the market today are the A3 and A4 size laminators. A3 comes in handy where large materials such as posters need to be protected while the A4 is suitable for homes, offices, and retail institutions.

Most models are intended for daily school activities since they have automated functions that offset the need to have regular programming whenever you want to use it.

For industrial use, you should choose a laminator able to withstand constant use with enough durability to withstand consistent use and high-end performance.

While choosing the ideal laminator may require an initial colossal investment, durability, maintenance, and efficiency is always a worthwhile investment.

Conclusion

Laminating machines come in a wide range of designs, user-friendliness, and sizes. To meet the constant business needs in such a volatile environment, you should consider purchasing one that meets your specific needs. After all, beyond your business needs, the environment and application are what matters for your usage.