The key to 3D printing both good-looking and useful products is to choose the best material. After all, the material used in 3D printing strongly influences the final output. But oftentimes, finding the ideal 3D printing material can be a task.

There are various types of 3D printing materials available in the market today. While each of them has distinct characteristics that can improve the quality of your work, you’ll need to pick according to the compatibility with your printer, cost, and malleability.

Here’s a look at some of the most common materials for home 3D printers that you can buy locally. These materials can be easily bought online and safely used on your desktop 3D printers.

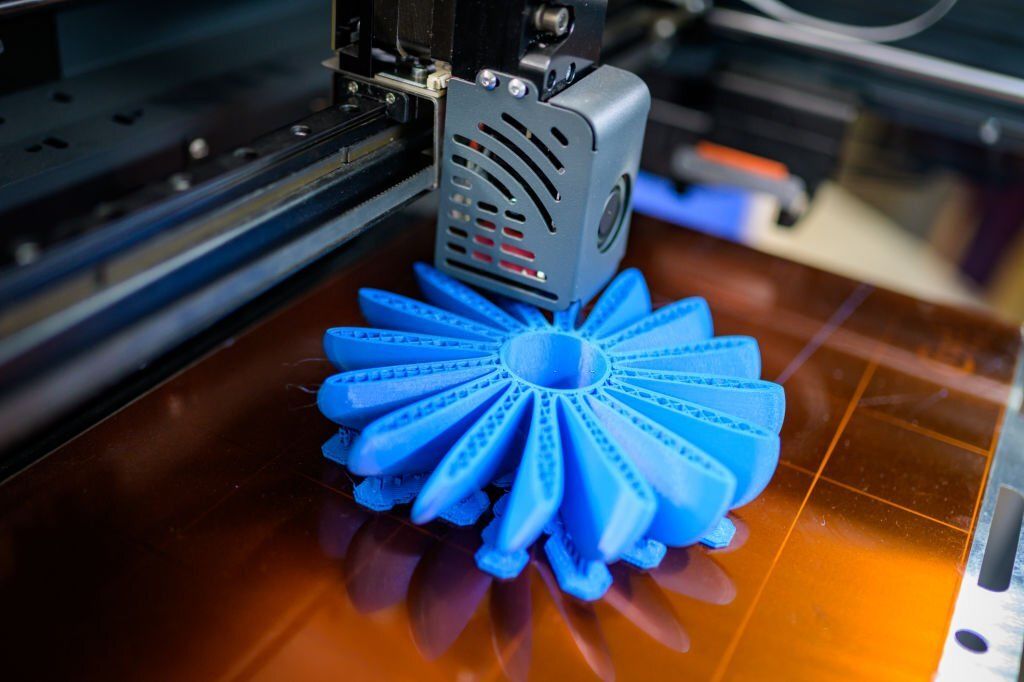

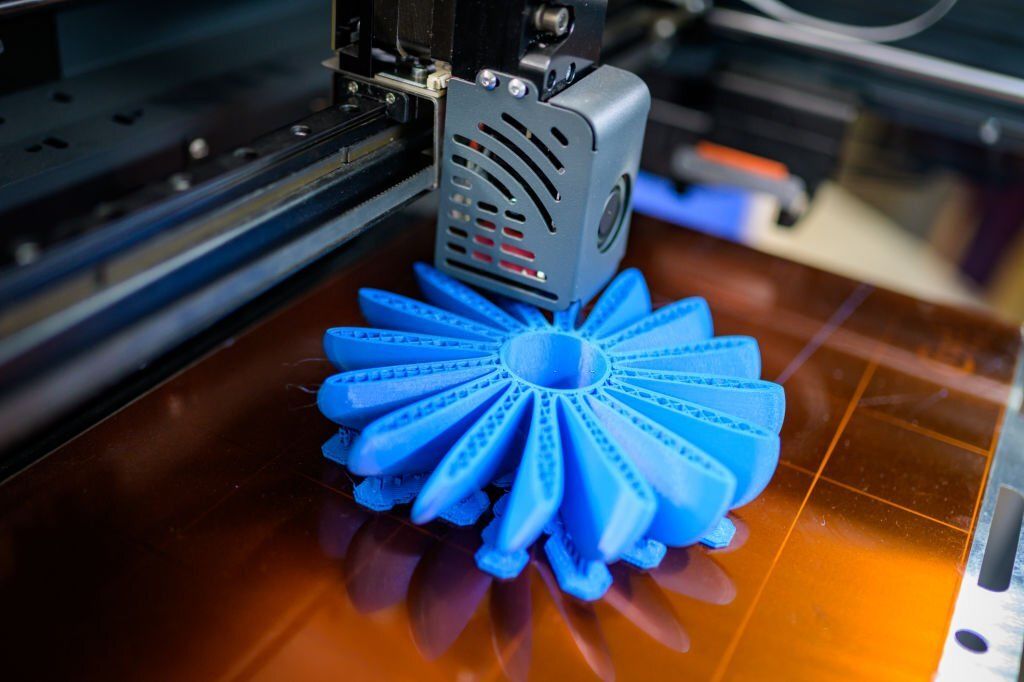

What is 3D Printing? How Does It Work?

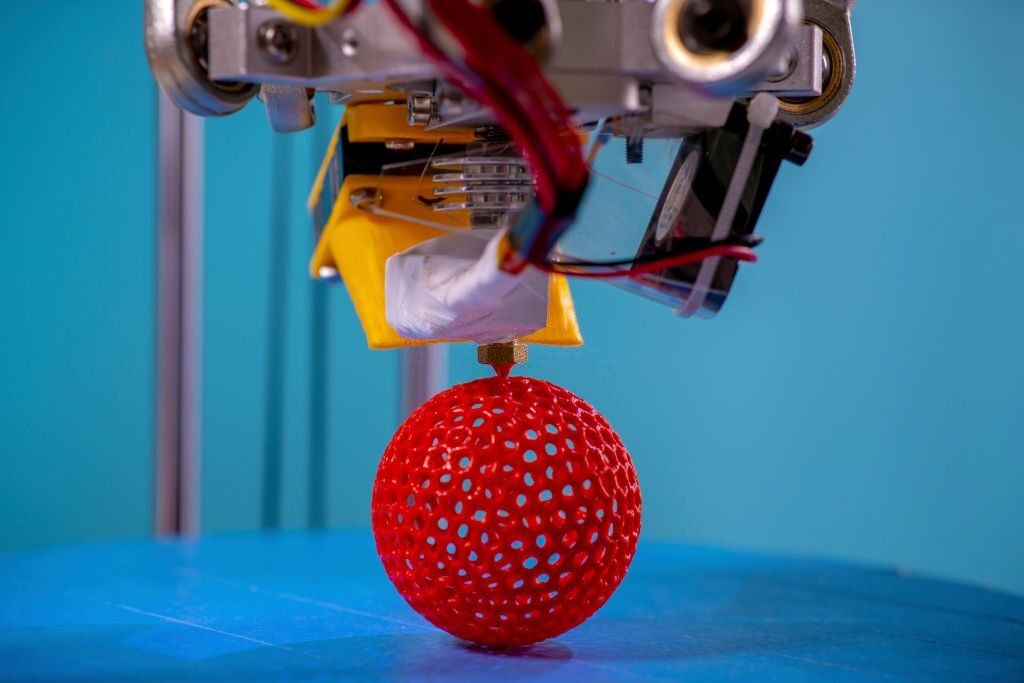

For the uninitiated, 3D printing converts a digital design into a three-dimensional model using materials such as filaments and resin. Also known as additive printing, it divides a digital design file into slices or layers and uses an extruder (or any 3D printing technology) to form a physical model. Entry-level 3D printing uses plastic and other synthetic materials to create anything from small souvenirs to household fixtures to toys.

The most basic feature of 3D printing is that it creates a 3D model using several layers. In effect, a digital design is first sliced into hundreds or thousands of slices or layers. This sliced-up file is then fed to the printer to develop the model (usually inside an enclosure). The printer then puts layers over layers vertically to print the final product.

In comparison, subtractive manufacturing involves carving or hollowing out a model made of a certain material. An example is wood sculpting.

3D printing has revolutionized the way certain objects like toys, fixtures, industrial parts, and medical implants are produced. It uses less volume of materials, is cost-effective, and is highly flexible.

Consumer 3D Printing Vs Professional 3D Printing

A consumer or desktop 3D printer was born out of the need to have an affordable and easy-to-use version of the original 3D printer. 3D printing from its origin has been a semi-industrial affair meant as a professional activity. However, the industry soon identified the benefits of expanding its user base beyond the pros.

Mainly targeted at hobbyists, DIYers, and home users, a consumer 3D printer is an amateur version of a professional 3D printer. It has all the basic functionalities of a pro 3D printer but with limited features.

For instance, FDM desktop 3D printers for hobbyists can be as small as 20 centimeters in height. Compare this with professional machines which can be as tall as an entire meter even. Moreover, professional printers typically use SLS or more advanced printing technologies.

Other differences include software compatibility, applications, and support. Professional 3D printers often have support communities and associations that assist them in their projects. They are often affiliated with industries and factories as opposed to domestic 3D printers that produce stuff on a smaller scale.

Differences in the 3D Printing Materials Uses

In the context of this guide, there are also major differences in the types of materials the desktop and professional printers use.

Desktop 3D printers commonly use thermoplastics as they are flexible, cheap, and easy to use. Subtypes of thermoplastics include polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). While these two have distinct features (which we’ll know more about in the next section), they make desktop printing easier and more accessible.

Anyone can walk to a local stationery shop and get a spool of PLA off the shelf in the United States. This ease of availability and use makes thermoplastics a crowd favorite among amateur 3D printers.

In contrast, professional 3D printers may employ materials such as metals, alloys, and customized, experimental filaments as part of research and development.

Another distinct difference lies in standardization. Off-the-shelf 3D printing materials often have standard sizes and lengths, unlike professional 3D supplies that are made to order or available in bulk.

3D Printer Materials for Home: Commonly Used Materials

Here’s a rundown on some of the most common 3D printing materials ideal for home users. To avoid confusion, we’ve only listed those materials that are safe and easy to use and handle at home.

Note: Desktop 3D printers typically utilize materials such as solid thermoplastics that are melted to create layers. In this guide, we’ll discuss different types of filaments, resins, and other common materials for home 3D printing.

1 – ABS

- High durability

- Resistance to high temperatures

- Highly flexible

- Affordable

- Emits a bad odor and toxic gases during melting and printing

- Requires 3D printing experience for successful outputs

Acrylonitrile butadiene styrene (ABS) is one of the toughest 3D printing material types out there. With a high resistance to temperature and high durability, it can be used to make virtually any everyday object.

Its affordability makes it a great choice for DIYers but it’s prone to warping. The printer bed must maintain an ideal temperature range to ensure that ABS sticks well and the final product does not warp. As you can guess, this requires a bit of printing experience.

ABS is made of petroleum, so it’s not exactly safe to use it to print products that interact with food (spoon, for instance) or personal care.

Applications

- Toys for kindergarteners

- Household and engineering tools

- Auto and electrical components

2 – HIPS or TPE

- High flexibility and durability

- Soluble in limonene

- Easily available over the counter

- Food-safe (FDA-compliant)

- Requires high maintenance during and after printing

High impact polystyrene or HIPS is a blend of synthetic plastic and rubber that retains their individual properties of strength and flexibility respectively. It is in the same league as ABS but has better resistance to pressure and external stimuli. This makes it an ideal material for mechanical and industrial objects and fixtures.

HIPS is also highly customizable as you can paint it, machine it, and blend it with other 3D printing consumer materials for better outputs. It also has solubility properties that also make it a good candidate as a secondary material instead of PVA.

TPE or thermoplastic elastomer is a type of HIPS. Both may be different based on the proportions of plastic and rubber. In some applications, TPE with a small proportion of soft rubber is used.

Applications

- Mechanical industry

- Automobiles, electricals

- Industrial objects that require high tensile strength

3 – Nylon

- High tensile strength

- High resistance to temperature

- Requires high temperatures for printing

Nylon or polyamide (PA) is a strong filament with high tensile strength and resistance. Along with ABS, nylon makes for a great choice for printing objects meant for high wear and tear. Originating from textiles, nylon as a 3D printing material can create moderately flexible products and withstand high temperatures.

Due to its easy availability and low cost, nylon has become one of the most common 3D printing materials. The only major drawback is that it requires a temperature as high as 250-degree Celsius to print. Working at such temperatures requires caution and experience.

Applications

- Mechanical and automobile components

- Electrical fixtures

- Household items

4 – PETG

- Translucent material

- Products look sharp, smooth, and clear

- Easy to use and maintain

- Poor blending/bridging

- Sticky outputs due to hygroscopic characteristics

PETG is a form of Polyethylene Terephthalate (PET) (the type in plastic bottles) with an additional component of ethylene glycol. This makes it stronger yet less brittle, translucent, and more flexible.

PETG is a great desktop 3D printing material type for those projects where you need the product to look sharp and clear. It is less prone to shrinkage and wear and tear, so your prints will have a better shelf life. This is why they are preferred for everyday home projects such as spoons, phone covers, and DIY projects.

Professionals who want to avoid the complexity of ABS usually prefer PETG. However, it does come with its fair share of disadvantages. High moisture absorption and poor bridging capability make it a secondary choice for some.

PETG provides aesthetically pleasing outputs so you may use it for any application that requires moderate-to-high temperature.

Applications

- Garden appliances and utensils

5 – PLA

- Low cost

- Requires low printing temperature

- Does not have an odor unlike ABS

- Low durability

- Not suitable for DIY engineering

PLA or polylactic acid is the most popular 3D printing material type today. This moderately biodegradable filament is easy to use as it melts in low temperatures. You can use it in any FDM home 3D printer to make everyday objects including those that deal with food. It’s less susceptible to warping and does not require a heated bed in most cases.

PLA comes in a wide variety of colors including glow-in-the-dark and glitter. This makes it a great choice for art, craft, and design projects.

The only drawback of PLA is that it is less durable than ABS and other filaments. We recommend using it only for basic objects, toys, and fixtures that are not exposed to much wear and tear.

Applications

- Small objects like toys and fixtures

- Household items and souvenirs

6 – PVA

- Highly soluble

- Good resistance to high temperatures

- Weak physical properties

- Not suitable as a primary 3D printing material

The most redeeming quality of polyvinyl alcohol or PVA is its solubility. Mostly used to create soluble products like detergent and water closet pods, PVA has high water content. Naturally, this makes it very difficult to handle and store. Most designers buy PVA spools off the shelf and use them immediately to avoid hardening.

PVA is rarely used as the primary 3D printing material. In most cases, it acts as a secondary filament during extrusion. It has excellent binding properties when placed on a heated bed, making it easier to handle along with ABS and HIPS.

Applications

- Detergent pods

- Fish baits

7 – Wood and Plastic Composite

- Good-looking prints

- Highly customizable in the post-printing stage

- Wears down 3D printer nozzles quickly

- Prone to burned-out outputs

Wood and plastic composite are types of PLA material with additives. Wood or plastic fibers are mixed into the material to get the intended texture, physical properties, and solubility.

These are typically used for their aesthetic qualities, and therefore, lack the flexibility and strength that the base materials are known for. Moreover, printers are not intrinsically made to print using these filaments, so you may require a bit of tweaking and customization to get the desired output.

These days, metal composites with small proportions of metal bits are also used to get metallic and optical properties.

Applications

- Souvenirs

- Arts and crafts

- Decoration and interior designing (panels)

8 – Polycarbonate

- Strong and durable

- Highly flexible

- High resistance to temperatures

- Hygroscopic in nature

- Hard to maintain and store

Also known as PC filament, polycarbonate is a type of thermoplastic with heat-resistant and insulation properties. It is extremely flexible and makes for a great choice for most 3D prints. Its high blending capability is another coveted property in 3D printing as it is easy to create layers from and join with other materials.

PC is easy to use, cheap, and available off the shelf.

Applications

- Medical appliances

- Electronic and electrical components

- Lamination

9 – Resins

- Quick printing

- Strong and flexible

- Smelly and sticky

- Difficult to handle than filaments

Resins are different from filaments as they are usually in the form of liquids and are used in advanced 3D printers like SLA and DLP. If you are looking for resins, opt for standard ones that are available in a wide range of colors and with different properties.

There are also rapid resins that cure quickly, tough resins for industrial tools, water-washable resins for medical instruments, and flexible resins. In effect, there’s a better and more flexible version of resin for every filament 3D printing material.

Applications

- Miniature models

- Fixtures

- Prototypes of products

- Visual arts

Miscellaneous Desktop 3D Printing Materials

Some of the other less common materials used in home 3D printing are:

- Conductive material like graphene (added to ABS, PLA)

- Plant-based resin

Conclusion

The wide range of 3D printing materials available in the market should not bother you. The best way to pick the right material for your project is to look at the properties of the filament and read the fine print on the spool.

If you’re looking for a soluble filament, opt for PLA or similar material. If strength is your goal, try ABS or HIPS.

We hope this guide has given you a beginner’s introduction to the common printing materials for home 3D printers. Why not give all of these a try and get a first-hand experience?

Share your thoughts in the comments below.